In modern food, feed, chemical and other industries, twin-screw extruders have become important equipment for efficient processing. As one of the core components of the extruder, the design of the barrel directly affects product quality, processing efficiency and energy consumption performance. At present, the mainstream barrel shapes in the market are divided into square barrels and round barrels, each of which has unique advantages and is suitable for different production needs.

This article will take you to an in-depth understanding of the advantages of the two barrels, helping enterprises to select more scientifically and produce more efficiently.

I. Advantages of square barrels

1. Stronger modular design flexibility

Square barrels usually adopt an assembled structure, which is easy to disassemble and replace internal bushings and modules. Users can quickly adjust the screw combination and barrel section length according to different process requirements to improve the adaptability of the equipment.

2. High heat exchange efficiency

The square shell can better arrange the cooling channel, enhance the heat exchange effect, help accurately control the temperature during the extrusion process, and improve product consistency and quality stability.

3. Easy maintenance

The square barrel is easy to disassemble and clean internally, shortening maintenance time, improving equipment availability, and reducing downtime costs.

4. High torque bearing capacity

Square barrels are usually designed to be more sturdy and have higher torsional strength, and can handle complex processing tasks with high torque and high load, such as puffing of high-fat and high-protein materials.

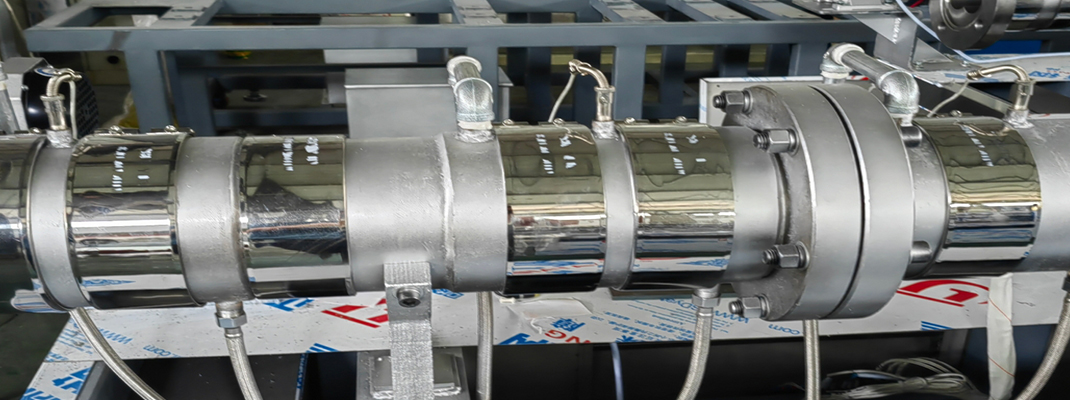

II. Advantages of round barrels

1. The manufacturing cost of the round barrel itself and the temperature control system are lower

The round barrel has a mature processing technology, high manufacturing precision, and relatively low cost, making it suitable for small and medium-sized production enterprises or cost-sensitive projects. The heater and water cooling system are easier to adapt and have a moderate cost. In addition, the round barrel is usually connected by a flange, which is convenient for workers to maintain and replace the barrel and the adapted heater.

2. Excellent inner wall wear resistance

The inner wall of the circular barrel is usually processed as a whole and has a good wear resistance life

3. The flow field of the screw movement is more uniform

It helps the material to form a more stable and uniform flow state between the screws, optimize the shearing, mixing, and heat conduction processes, and improve the structural quality of the final product.

4. Suitable for standardized batch production

The circular barrel is the most mature and stable design with a high degree of standardization. It is suitable for enterprises to purchase and quickly deliver conventional twin-screw extruders in large quantities, greatly shortening the delivery cycle of the whole machine and the whole production line.

According to the production craft, raw materials and specific requirements for the barrel material etc, Joyang Machinery will provide the most suitable production line solution for users.

Welcome your inquiry!